Abrasive is a tool used for shaping or giving a fine finish to the workpiece by rubbing. By doing this, the friction wears away some part of the workpiece. It can also do the detailing of a workpiece, i.e. polishing to get a silky, smooth and shiny surface. Abrasives include a range of products from flap wheels to flap discs, and many things in between. It is commonly used in industrial, domestic, and technological applications. We offer this handy comparison chart to help you decide which abrasive will work best for your application for a quick look.

| Product | Flap wheels | Abrasive belt | Cross pads | Flap disc | Flap wheel with shank |

| Features | This product can absolutely match the workpieces,and it provides a smooth abrasion on the workpieces's surface during it's lifetime.It has the characteristics of good elasticity,stable physicochemical property,high security,and safe not to burn the workpieces.Also,the product can be easily and conveniently operated. | It can be specialized by customer's requirements. It has several sizes to choose from and has a high tensile strength and great tension. | Abrasive material under special production procedure,the nature advantages includes strong elasticity and strength,good heat dissipation,protection from the burn of the workpieces,as well as hands-free installation,smoothly working and good control of voice under operation. | We use the substrate was pressured by internal and external,it can be installed in mechanical arm,and disassemble & assemble automatically.So the product can be easily and conveniently operated. | The advantages including as followings: high tensile strength,grinding sharpness, fast cooling, perfected surface treatment, protection from the burn of the workpieces, as well as hands-free installation, smoothly working and good control of voice under operation |

| Application | This product can be applied to most irregular surfaces and both inner and outer wall of pipes. | It is widely used in the industries like metallurgy,machines,ship building,light industry,lumbering,stainless steel,and artificial stone. | It's a perfect material major used for polishing inner-wall of high qualified stainless steel tube and pipe fittings,it was mainly installed in the elbow automatic polishing machines and tube polishing machines. | Mainly used for small areas of the car, and the welding seam on groove, it's online automatic polishing. | Coordinate with pneumatic or electric hand grinder can polish metal or non metallic surface,variety of small gaps,slot seam which not easy to handle and the cavity parts. |

If you work with abrasives frequently, you already know you need different ones for different jobs. And JSH offers a variety of abrasives for every job, but how do you know which one to choose? Which abrasive grain is ideal for your application? Abrasives can be confusing and expensive, especially if you don’t know the ideal applications for each type. Here is a breakdown of the common types of abrasive grains, how they perform, how long they last and their ideal uses:

Flap wheels are made of multiple abrasive sheets attached to a core for fabricating, deburring, cleaning, polishing, and finishing jobs in metalworking applications. The sheets wear away during jobs, constantly exposing the fresh abrasive coating to provide an even finish. The stainless-steel polishing flap wheel can be installed on the tube maker and the stainless-steel pipe polishing machine, and they have versatile flap wheel grit sizes.

Slashed flap wheels are widely used on the irregular surface of woodworks, soft metals, and also can be assembled for the auto polishing machine. We have introduced things you need to know about flap wheels in our recent article. Of course, if you need a refresher, you can check out our most recent blog, just to be sure.

Industrial abrasive belts are mounted on rotating wheels or pulleys and are used in applications such as surface finishing, sanding, and grinding. Abrasive belt tools can be used throughout a body shop for a variety of sanding, blending, and finishing applications. It can be installed on the oil mill or the square tube drawing machine.

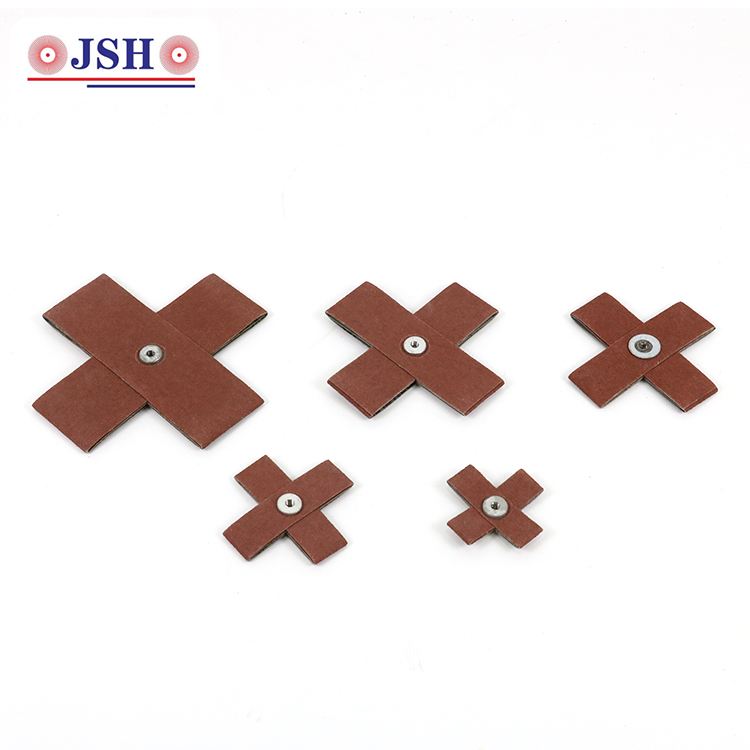

Cross pads are a specialty abrasive made up of abrasive flaps folded over one another in a t-shape/plus sign/cross shape, which gets fitted onto a die grinder or rotary drill through a mandrel attachment. This product is made from sharp abrasive materials. It has a good elasticity feature and it is for easy replacement.

It’s a perfect material major used for polishing inner-wall of high qualified stainless-steel tuber and pipe fittings. Installed on the automatic polishing machine for stainless steel long pipes or elbows, used for polishing the inner wall of stainless steel long pipes and stainless steel long and short elbows, tees, etc.

A flap disc set is an abrasive product designed for right-angle grinder applications that consist of overlapping abrasive “flaps” glued radially to a backing plate. The flap disc wheel has a long lifetime as calcined abrasive and zirconia alumina, better wear-resistant, self-sharpening, toughness, and hi-grinding power.

The flap wheel with shank by JSH is the ideal choice for polishing, flash removal, light grinding, deburring, scale removal, blending, and graining in small spaces, such as the inside or outside of pipes or tubes. Coordinate with pneumatic or electric hand grinder can polish metal or nonmetallic surface, variety of small gaps, slot seam which not easy to handle and the cavity parts.

| Product | Flap wheels | Abrasive belt | Cross pads | Flap disc | Flap wheel with shank |

| Size avaliable | 120# /180# /240# /320# /400#/ 600# /800#/ 1000# | customized | 1/2"-8'' | customized | 36#/40#/60#/80#/100#/120#/150#/180#/220#/240#/320#/400#/600#/800#/1000#/1200# |

The motive of presenting this article is the categorization of abrasives and simplifying the classification of abrasive belts or abrasive flap wheels. It gives you a brief idea of each abrasive & uses to relate it with your application. It will save not only your time but also the efforts that you put into research work for finding the suitable abrasive type. JSH offers versatile abrasives for every job, we look forward to working with you.